Products

Products

-

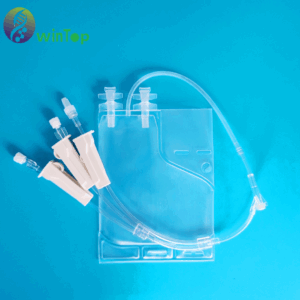

winTop therapy® Cell Cryopreservation Bag (50mL)

Rated 0 out of 5

winTop therapy® Cell Cryopreservation Bag (50mL)

Rated 0 out of 5 -

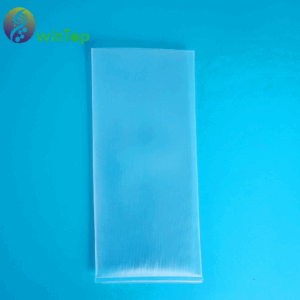

winTop therapy® Cell Cryopreservation Bag (15mL) (excluding label area)

Rated 0 out of 5

winTop therapy® Cell Cryopreservation Bag (15mL) (excluding label area)

Rated 0 out of 5 -

winTop therapy® Cell Cryopreservation Bag (250mL)

Rated 0 out of 5

winTop therapy® Cell Cryopreservation Bag (250mL)

Rated 0 out of 5 -

winTop therapy® Cell Cryopreservation Bag (50mL)(excluding label area)

Rated 0 out of 5

winTop therapy® Cell Cryopreservation Bag (50mL)(excluding label area)

Rated 0 out of 5 -

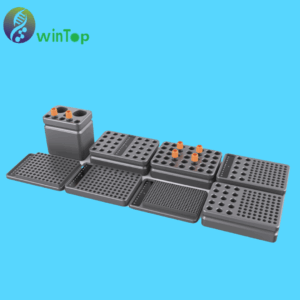

Alcohol-Free Cell Freezing Containers (For Cryobags)

Rated 0 out of 5

Alcohol-Free Cell Freezing Containers (For Cryobags)

Rated 0 out of 5

-

Cell Cryopreservation Bag 50mL

winTop therapy® Cell Cryopreservation Bag (50mL)

Read moreRated 0 out of 5 -

Cell Cryopreservation Bag 15mL

winTop therapy® Cell Cryopreservation Bag (15mL) (excluding label area)

Read moreRated 0 out of 5 -

Cell Cryopreservation Bag 250mL

winTop therapy® Cell Cryopreservation Bag (250mL)

Read moreRated 0 out of 5 -

Cell Cryopreservation Bag 50mL

winTop therapy® Cell Cryopreservation Bag (50mL)(excluding label area)

Read moreRated 0 out of 5 -

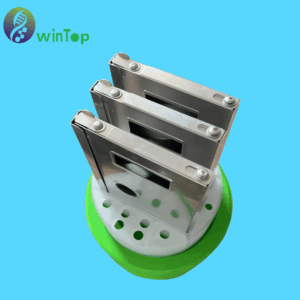

Alcohol-Free Cell Freezing Containers

Alcohol-Free Cell Freezing Containers (For Cryobags)

Read moreRated 0 out of 5 -

Alcohol-Free Cell Freezing Containers

Alcohol-Free Cell Freezing Container CellHome Series (For Cryotubes)

Read moreRated 0 out of 5 -

Cryopreservation Consumables

winTop therapy® Cell Cryopreservation Bag (15mL)

Read moreRated 0 out of 5 -

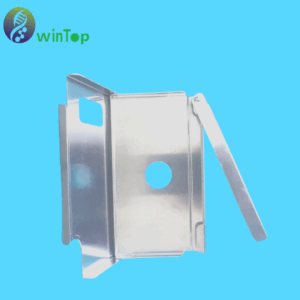

Blood Bag Holders

Flip-top Aluminum Alloy Blood Bag Holder/Rack(50mL/250mL)

Read moreRated 0 out of 5

1. Can the liquid volume in cryobags exceed the recommended capacity?

No. Exceeding the recommended fill volume may lead to:

- Risk of rupture: Liquid expansion during freezing can cause cracks or leaks.

- Sealing failure: Overfilling may compromise the closure, leading to contamination.

- Storage inefficiency: Overfilled bags hinder stacking and occupy excess space.

Always adhere to the labeled capacity for optimal performance.

2. Why is gas removal critical when loading samples into cryobags?

Degassing ensures:

- Reduced ice crystal formation, minimizing cell damage.

- Secure sealing by eliminating air pockets.

- Uniform freezing and prevention of bag rupture.

- Higher cell viability post-thaw.

Always expel air before sealing to maximize sample integrity.

3. What precautions should be taken during cryobag heat sealing?

- Adjust temperature/time based on material (PVC, EVA).

- Apply even pressure for consistent seals.

- Clean and dry the sealing area to avoid residue interference.

- Align edges precisely before sealing.

- Use validated equipment (e.g., RF heat sealers).

- Inspect seals post-process for leaks.

4. How to properly cool cryobags for freezing?

- Use controlled-rate freezing:

- Initial cooling rate: ~1°C per minute (or per protocol).

- Avoid abrupt temperature drops to prevent thermal shock.

- Employ programmable freezers for precision.

- Never place bags directly into liquid nitrogen without gradual cooling.

Slow cooling minimizes ice crystal damage and maintains cell viability.

5. What is the correct thawing procedure for cryobags?

- Rapid thawing: Submerge in 37°C water bath (≤40°C) for 2–3 minutes until ice melts.

- Avoid water contact: Use a sealed secondary bag if necessary.

- Gentle agitation: Swirl gently to ensure even warming.

- Aseptic transfer: Move thawed samples to sterile conditions immediately.

- Inspect integrity: Check for leaks before use.